Challenge

Product complexity is exponential growing. Customers want customized products with 24-hour delivery. Manufacturers need to reconcile this with fixed production lines that are adapted to high volume, standardized products. At the same time, manufacturers have to go to market faster, keep up with high quality standards and ensure cost-effectiveness.

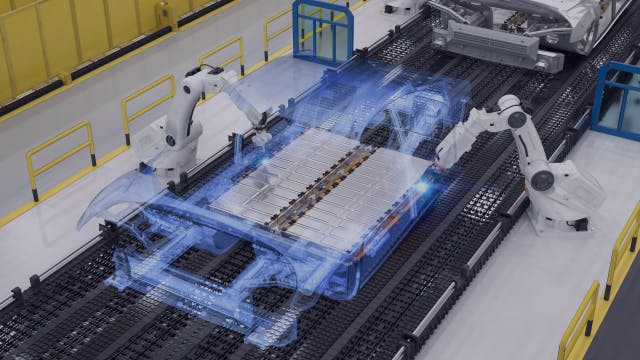

Solution

This solution enables you to respond to market demands for customized products while optimizing operational efficiency so you remain cost-effective and go to market fast.